Introduction

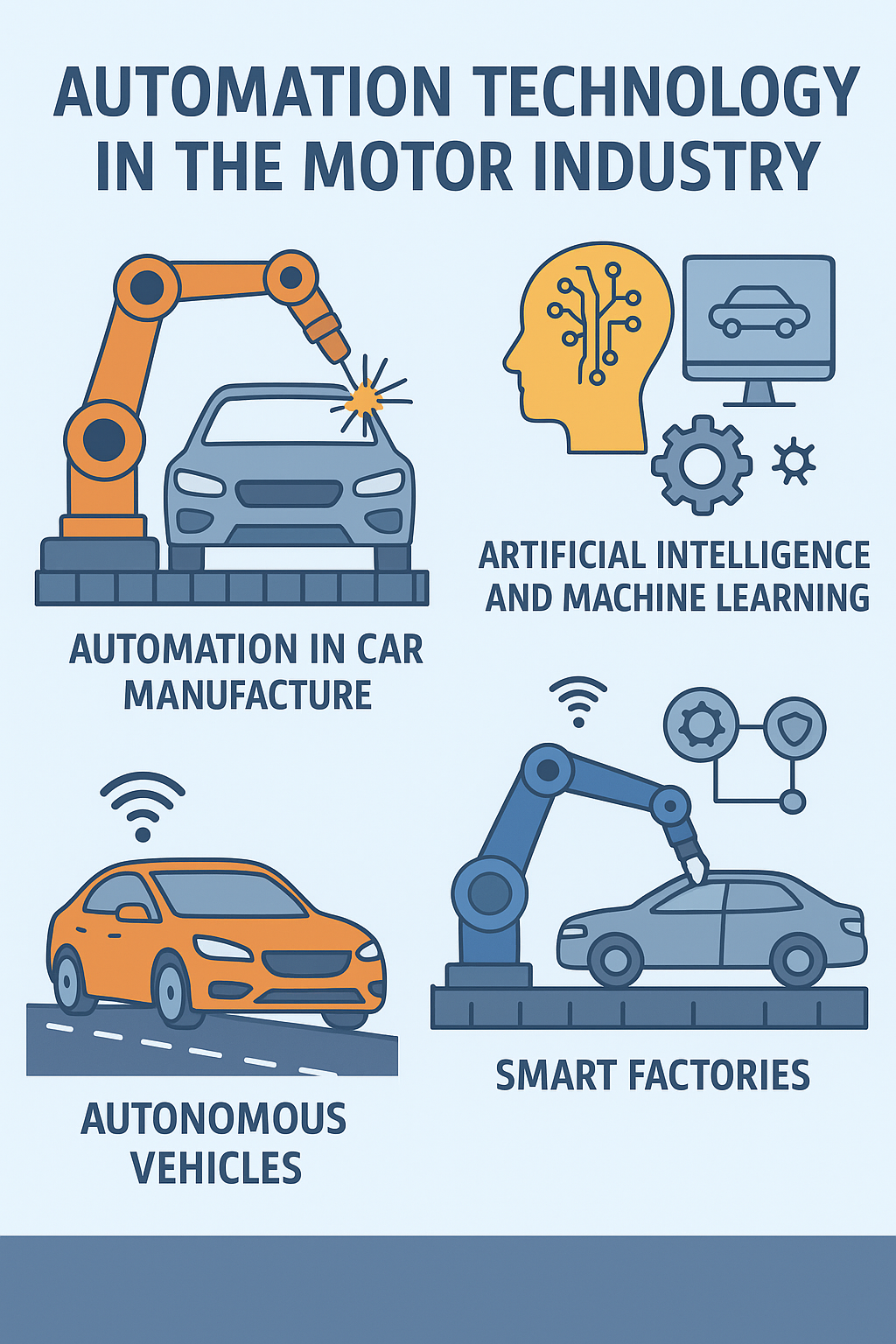

The automotive industry stands at the forefront of one of the most significant technological transformations in manufacturing history. Automation technology has fundamentally reshaped how vehicles are designed, produced, and delivered to consumers. From robotic assembly lines to artificial intelligence-driven quality control systems, automation has become the backbone of modern automotive manufacturing, driving unprecedented levels of efficiency, precision, and innovation.

The Evolution of Automotive Automation

The journey of automation in the motor industry began in the 1960s when General Motors introduced the first industrial robot, Unimate, to its assembly line. This revolutionary machine performed tasks that were dangerous and repetitive for human workers, such as handling hot metal parts and welding. Since then, automation has evolved exponentially, moving from simple mechanical tasks to complex, interconnected systems powered by artificial intelligence and machine learning.

Today’s automotive factories bear little resemblance to their predecessors. Modern facilities are highly orchestrated environments where robots, computers, and human workers collaborate seamlessly. These smart factories utilize the Internet of Things (IoT) to connect machinery, sensors, and software systems, creating a digital ecosystem that optimizes every aspect of production.

Key Automation Technologies Transforming the Industry

Robotic Assembly and Manufacturing

Industrial robots remain the most visible symbol of automotive automation. Modern robotic systems are far more sophisticated than their predecessors, capable of performing intricate tasks with microscopic precision. Collaborative robots, or “cobots,” work alongside human employees, combining the strength and consistency of machines with human problem-solving and adaptability. These robots handle everything from welding and painting to installing windshields and mounting engines, performing thousands of repetitive motions with perfect consistency.

Artificial Intelligence and Machine Learning

AI has emerged as a game-changer in automotive manufacturing. Machine learning algorithms analyze vast amounts of production data to identify patterns, predict equipment failures before they occur, and optimize manufacturing processes in real-time. AI-powered vision systems inspect vehicles for defects with greater accuracy than human inspectors, detecting imperfections as small as a fraction of a millimeter. These systems learn continuously, improving their performance with every vehicle they inspect.

Autonomous Guided Vehicles

Within manufacturing facilities, autonomous guided vehicles (AGVs) have revolutionized material handling and logistics. These self-driving vehicles transport parts, components, and finished products throughout the factory without human intervention. Equipped with sensors and navigation systems, AGVs follow predetermined routes or adapt dynamically to changing conditions, ensuring that materials arrive at the right place at precisely the right time.

Digital Twin Technology

Digital twins create virtual replicas of physical manufacturing processes, allowing engineers to simulate and optimize production before implementing changes on the factory floor. This technology enables manufacturers to test new processes, identify bottlenecks, and perfect production sequences in a risk-free digital environment. The result is faster innovation cycles and reduced downtime when implementing new manufacturing techniques.

Benefits of Automation in Automotive Manufacturing

Enhanced Productivity and Efficiency

Automation has dramatically increased production rates while reducing manufacturing time. Robots work continuously without breaks, fatigue, or shift changes, enabling 24/7 production capabilities. Tasks that once took hours can now be completed in minutes, and entire vehicles can be assembled in a fraction of the time required by traditional methods. This increased efficiency translates directly into higher output volumes and reduced per-unit costs.

Superior Quality and Consistency

Automated systems perform tasks with unwavering precision, eliminating human error and ensuring that every vehicle meets exact specifications. Consistency across thousands of vehicles becomes achievable when robots perform critical operations. Automated quality control systems catch defects early in the production process, reducing waste and warranty claims while enhancing customer satisfaction.

Improved Worker Safety

Automation has removed humans from many dangerous manufacturing tasks. Robots handle toxic materials, operate in extreme temperatures, and perform physically demanding operations that once led to workplace injuries. Workers are freed from repetitive strain injuries and can focus on more skilled, rewarding tasks such as programming, maintenance, and quality oversight.

Cost Reduction and Competitiveness

While the initial investment in automation technology is substantial, the long-term cost savings are significant. Reduced labor costs, minimized waste, lower defect rates, and increased production speed all contribute to a healthier bottom line. These efficiencies allow manufacturers to remain competitive in an increasingly global marketplace while maintaining profitability.

Challenges and Considerations

Workforce Displacement and Transformation

The most pressing concern surrounding automotive automation is its impact on employment. As robots and AI systems take over tasks previously performed by humans, manufacturing jobs are being eliminated or fundamentally transformed. Workers must acquire new skills to remain relevant in automated environments, focusing on robot programming, system maintenance, and data analysis rather than manual assembly tasks.

Progressive manufacturers are investing heavily in workforce retraining programs, helping employees transition from traditional manufacturing roles to technical positions that support automated systems. However, the transition remains challenging for many workers, particularly those in regions heavily dependent on automotive manufacturing employment.

High Implementation Costs

The financial barrier to automation remains significant, especially for smaller manufacturers. Advanced robotic systems, AI software, and the infrastructure required to support them demand substantial capital investment. Additionally, ongoing costs for maintenance, software updates, and system upgrades can strain budgets. Manufacturers must carefully balance the long-term benefits of automation against immediate financial pressures.

Cybersecurity Vulnerabilities

As automotive manufacturing becomes increasingly connected and data-driven, cybersecurity emerges as a critical concern. Interconnected systems create potential entry points for cyberattacks that could disrupt production, steal intellectual property, or compromise vehicle safety. Manufacturers must invest in robust cybersecurity measures and remain vigilant against evolving threats.

Technological Complexity

The sophistication of modern automation systems introduces new challenges. Integration of diverse technologies from multiple vendors can be problematic, and troubleshooting complex automated systems requires specialized expertise. System failures can halt entire production lines, and the interdependence of automated systems means that problems can cascade rapidly.

The Future of Automotive Automation

Electric Vehicle Revolution

The shift toward electric vehicles is accelerating automotive automation. EV manufacturing requires different processes than traditional internal combustion vehicles, with greater emphasis on battery production and electric motor assembly. These processes lend themselves particularly well to automation, featuring fewer moving parts and more standardized components than conventional powertrains.

Advanced Materials and 3D Printing

Additive manufacturing, or 3D printing, is beginning to transform automotive production. This technology enables manufacturers to produce complex parts on demand, reducing inventory costs and enabling greater customization. As 3D printing technology matures, it may revolutionize how vehicles are manufactured, moving from mass production to mass customization.

Autonomous Factory Management

The factories of the future will be self-managing ecosystems where AI systems orchestrate entire production processes with minimal human intervention. These facilities will use predictive analytics to anticipate and prevent problems, automatically adjust production schedules based on demand, and continuously optimize operations for maximum efficiency and minimal environmental impact.

Human-Robot Collaboration

Rather than replacing humans entirely, the future of automotive manufacturing lies in enhanced collaboration between people and machines. Advanced cobots will work safely alongside human workers, combining robotic precision and strength with human creativity and judgment. Augmented reality systems will guide workers through complex tasks, overlaying digital information onto the physical world to improve accuracy and efficiency.

Conclusion

Automation technology has irrevocably transformed the motor industry, driving unprecedented improvements in productivity, quality, and efficiency. While challenges remain, particularly regarding workforce adaptation and the high costs of implementation, the trajectory is clear: automation will continue to expand and evolve, reshaping automotive manufacturing in ways we are only beginning to imagine.

The most successful automotive manufacturers will be those that embrace automation strategically, balancing technological advancement with human capital development. As we move forward, the goal should not be to eliminate human workers but to augment human capabilities, creating a synergistic relationship between people and machines that leverages the strengths of both.

The automotive industry has always been a bellwether for manufacturing innovation. As automation technology continues to advance, the lessons learned and solutions developed in automotive manufacturing will likely spread to other industries, driving a broader transformation in how we make things. The future of automotive manufacturing is automated, intelligent, and more efficient than ever before, promising vehicles that are safer, more affordable, and more sustainable for generations to come.

Be First to Comment