Introduction

Fabric, the foundational material of clothing, upholstery, and countless everyday items, has woven itself into the very fabric of human civilization. From rudimentary wraps of animal hides in prehistoric times to today’s high-tech, sustainable textiles, fabric represents ingenuity, adaptation, and cultural exchange. This article explores the anatomy and origins of fabric, its rich historical tapestry, the leading global producers as of 2025, and the transformative role of automation and artificial intelligence (AI) in modern manufacturing. As we navigate an era of rapid technological advancement, understanding fabric’s journey illuminates not just our past, but the sustainable, efficient future ahead.

Anatomy of Fabric: Structure and Composition

At its core, fabric is a flexible material produced by weaving, knitting, felting, or bonding fibers or yarns. Its “anatomy” refers to the interplay of fibers, yarns, construction methods, and properties that determine its texture, durability, and use. Understanding this structure is essential for designers, manufacturers, and consumers alike.

Fibers: The Building Blocks

Fibers are the raw strands that form fabric. They fall into three main categories:

- Natural Fibers: Derived from plants (e.g., cotton, linen from flax, hemp) or animals (e.g., wool from sheep, silk from silkworms). These are breathable and biodegradable but can wrinkle or shrink.

- Synthetic Fibers: Man-made from chemicals like petroleum (e.g., polyester, nylon, acrylic). Introduced in the early 20th century, they offer durability, elasticity, and wrinkle resistance but raise environmental concerns due to non-biodegradability.

- Regenerated Fibers: Semi-synthetic, like rayon (from cellulose) or lyocell, blending natural sources with chemical processing for enhanced softness and sustainability.

Fibers vary in length (staple for cotton vs. filament for silk), fineness, and properties like moisture absorption or elasticity.

Yarns: Twisted Foundations

Fibers are spun into yarns—continuous strands twisted or bonded together. Yarn types include:

- Spun Yarns: Short fibers twisted for a textured feel (e.g., cotton yarns for denim).

- Filament Yarns: Long, smooth strands for silky fabrics. Yarn count (thickness) and twist direction affect fabric strength and drape.

Construction: Weaving, Knitting, and Beyond

The method of assembling yarns defines fabric structure:

- Woven Fabrics: Interlaced warp (lengthwise) and weft (crosswise) yarns on a loom. Common weaves include:

- Plain (balanced, like muslin).

- Twill (diagonal ribs, like denim).

- Satin (smooth sheen, like silk). Wovens are stable and crisp, ideal for structured garments.

- Knitted Fabrics: Interlooped yarns, stretchy and form-fitting (e.g., jersey for t-shirts). Weft knitting (single yarn) vs. warp knitting (multiple yarns) offers different elasticity.

- Non-Wovens: Bonded fibers without weaving/knitting (e.g., felt or disposable wipes), used for filtration or medical textiles.

Key directional terms include:

- Grain: Straight (warp/weft) for stability; bias (45° angle) for stretch and drape.

- Selvage: Factory-finished edges, preventing fraying.

- Nap/Pile: Raised surface fibers (e.g., velvet) for texture.

Properties like weight (measured in GSM—grams per square meter), drape (how it falls), and finish (e.g., dyeing, printing) further refine fabric’s anatomy, influencing everything from a shirt’s collar to a tent’s weather resistance.mixmeasuremake.com

Origins of Fabric: The Dawn of Textiles

The story of fabric begins in prehistory, evolving from necessity to artistry. Archaeological evidence traces textiles to around 100,000 years ago, when early humans used felted animal hides or plant fibers for rudimentary coverings. By 27,000 BCE, impressions of woven cloth appear on clay artifacts in the Czech Republic, suggesting flax or nettle fibers.butterflyfabricsnyc.com

Early Developments

- Neolithic Era (c. 6000 BCE): Woolen textiles emerge in Anatolia (modern Turkey), while cotton cultivation begins in the Indus Valley (India/Pakistan) around 5000 BCE. In Egypt, flax linen wraps mummies, dyed with natural pigments from plants and minerals as early as 10,200 BCE.textileheritagemuseum.orgiwantfabric.com

- Ancient Civilizations: Silk production starts in China (2700 BCE), guarded as a secret until the Silk Road (c. 114 BCE) spreads it westward, fostering trade between empires. The Harappan civilization in India dyes cotton with natural colors, while Mesoamericans weave agave fibers.en.wikipedia.orgbutterflyfabricsnyc.com

Techniques like felting (matting fibers) predated weaving, with the latter enabled by looms—simple frames evolving into complex devices.

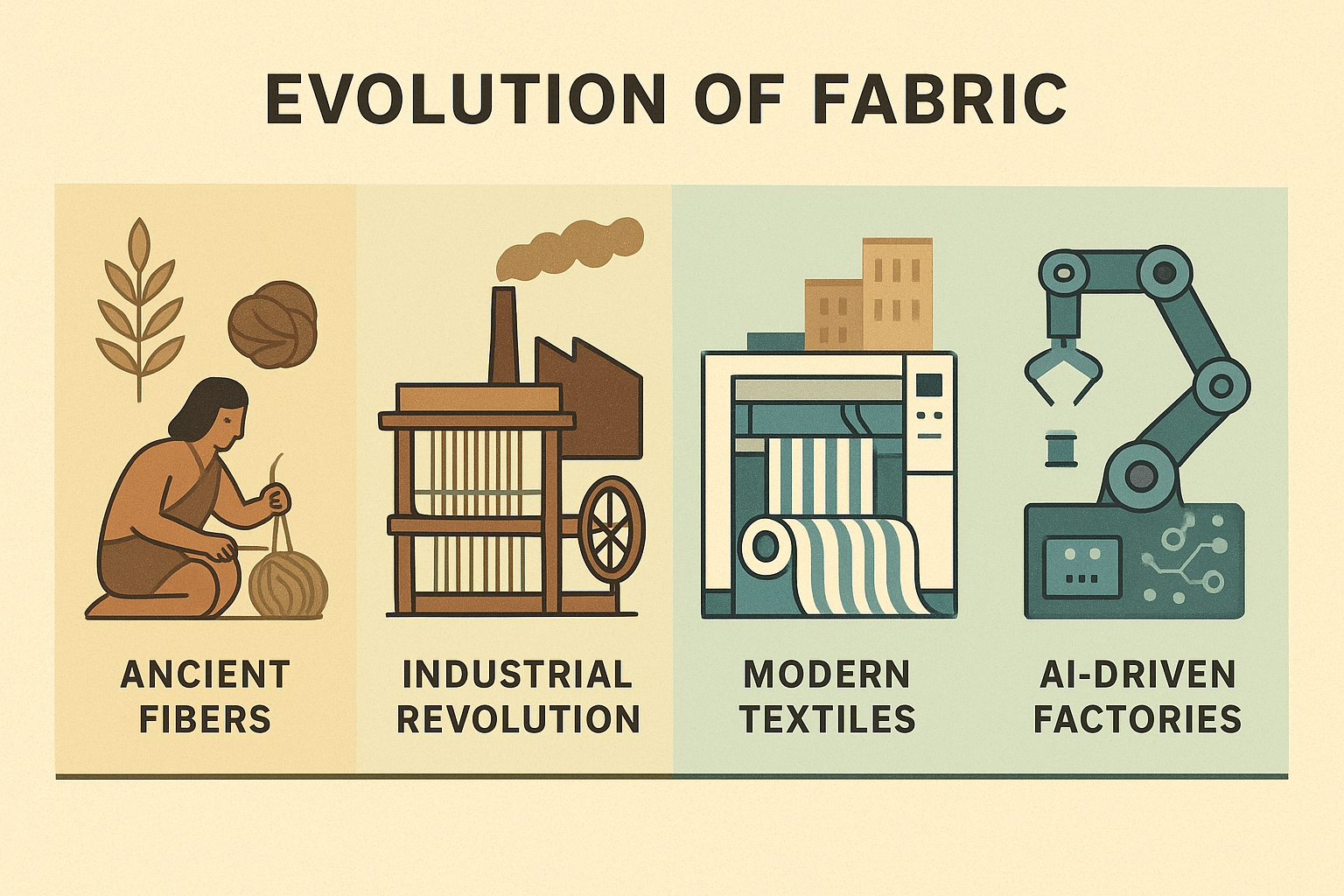

History of Fabric: From Handlooms to Industrial Revolution

Fabric’s history mirrors societal progress, from agrarian crafts to global industries.

Medieval to Renaissance (500–1600 CE)

Wool dominated Europe, with guilds regulating production. The Silk Road exchanged luxury textiles, influencing Islamic, Byzantine, and Indian designs. In Japan, the Yayoi period (c. 300 BCE–300 CE) shifted to agrarian wraps, while Renaissance Europe embraced velvets and brocades for opulence.en.wikipedia.orgiwantfabric.com

Industrial Revolution (18th–19th Centuries)

Inventions like the spinning jenny (1764), water frame (1769), and power loom (1785) mechanized production, shifting from home-based to factory systems. Britain’s cotton mills exploded, but at human cost—child labor and poor conditions sparked reforms. Synthetic dyes (1856, by William Perkin) and rayon (early 1900s) diversified colors and materials.blog.patra.comso-sew-easy.com

20th Century and Beyond

Post-WWII synthetics like nylon (1935) and spandex (1959) enabled stretchy, affordable clothing. The 1980s saw ultrasuede and naturally colored cottons, while today’s focus is sustainability—recycled polyester and bio-based fibers address environmental impacts. Global trade, via routes like the Silk Road’s modern equivalents, continues to shape fashion and economy.textileheritagemuseum.orgthoughtco.com

Biggest Producing Countries in 2025

As of 2025, the global textile market exceeds $640 billion, with Asia dominating production and exports (over 70% share). China leads unchallenged, but diversification via trade agreements boosts emerging players. Below is a table of the top five textile-exporting countries based on 2023–2024 data (projected stable into 2025), valued in billions of USD.developmentaid.org

| Rank | Country | Export Value (2024 est., USD Bn) | Key Strengths |

|---|---|---|---|

| 1 | China | 303 | Vast capacity; synthetics, apparel; supplies 40% of global market. |

| 2 | Bangladesh | 57.7 | Low-cost RMG (ready-made garments); cotton knits. |

| 3 | Vietnam | 48.8 | Trade pacts (e.g., EVFTA); activewear, denim. |

| 4 | India | 40+ | Cotton, silk; organic and technical textiles. |

| 5 | Turkey | 36.7 | High-quality wool/synthetics; quick turnaround. |

These nations leverage skilled labor, raw materials (e.g., India’s cotton), and policies like Vietnam’s tariff reductions to 0% by 2025. Europe (Italy, Germany) excels in premium and technical fabrics, exporting $57B and $40B respectively.thygesenapparel.comcosmosourcing.com

Present Automation and AI in Fabric Manufacturing

In 2025, Industry 4.0 has revolutionized fabric production, with automation and AI addressing labor shortages, waste, and sustainability. Global investments in smart factories exceed $200 billion annually, driven by AI’s predictive power and robotics’ precision.rockwellautomation.comarcherpoint.com

Key Trends

- AI-Driven Optimization: Machine learning analyzes data for predictive maintenance, reducing downtime by 30–50%. AI algorithms optimize yarn spinning and weaving, minimizing defects via computer vision—detecting flaws invisible to the human eye. In design, generative AI creates patterns based on trends, enabling mass customization.textilefocus.com

- Robotics and Cobots: Collaborative robots (cobots) handle repetitive tasks like cutting and sewing, working alongside humans for safer, faster lines. Automated looms with AI guidance cut fabric waste by 15% through precise pattern matching.advancedtech.comtextileschool.com

- IIoT and Digital Twins: The Industrial Internet of Things (IIoT) connects machines for real-time monitoring, while digital twins—virtual replicas—simulate production to test efficiencies. This supports sustainable practices, like energy optimization in dyeing.

- Sustainability Focus: AI tracks supply chains for traceability (via blockchain), reducing water use in wet processing by 20% and enabling recycled fiber sorting. Reshoring accelerates as AI lowers costs for localized production.hanwha.comscip.org

By 2025, these technologies have boosted efficiency by 25% industry-wide, with AI forecasting trends to cut overproduction. Challenges remain, like data privacy and workforce reskilling, but the result is greener, smarter fabric ecosystems.automationworld.com

Conclusion

Fabric’s evolution—from Neolithic flax to AI-optimized synthetics—encapsulates human resilience and innovation. As top producers like China and Vietnam scale output amid global demands, automation and AI ensure this ancient craft thrives sustainably. In a world of fast fashion and climate urgency, fabric’s future lies in smart, ethical manufacturing, promising textiles that are not just wearable, but wise.

Be First to Comment